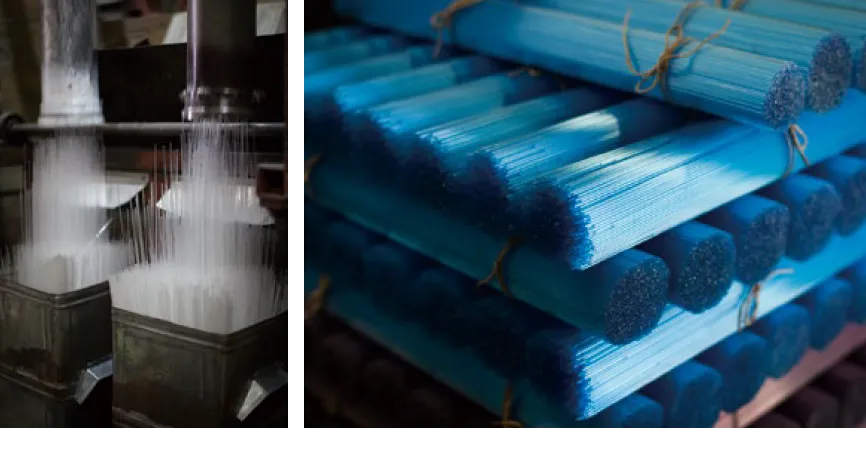

1. Glass Cane Making

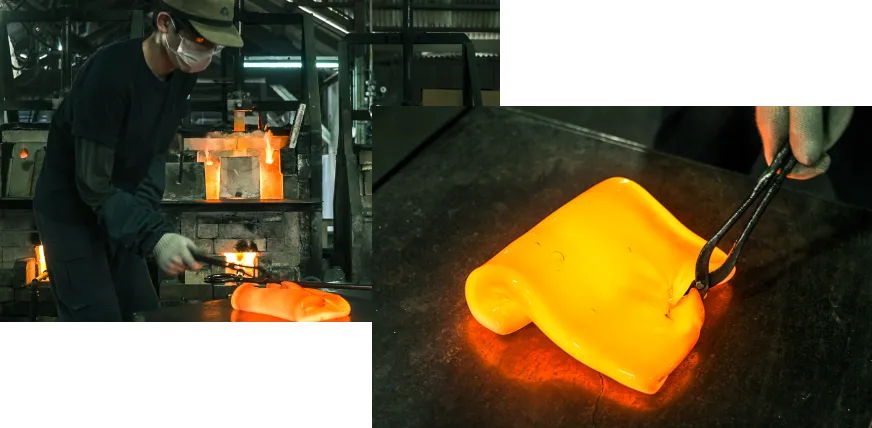

Melting

Main materials, coloring materials and opalizers are heated in a furnace.

Drawing

The molten glass is scooped out onto a metal plate. It is then folded until it cools to a temperature suitable for drawing the glass into canes.

The cooled glass substrate is placed in a cane shaping pot, from which, as air is blown through the center, it is drawn out into a long, thin cane shape by a pulling machine.

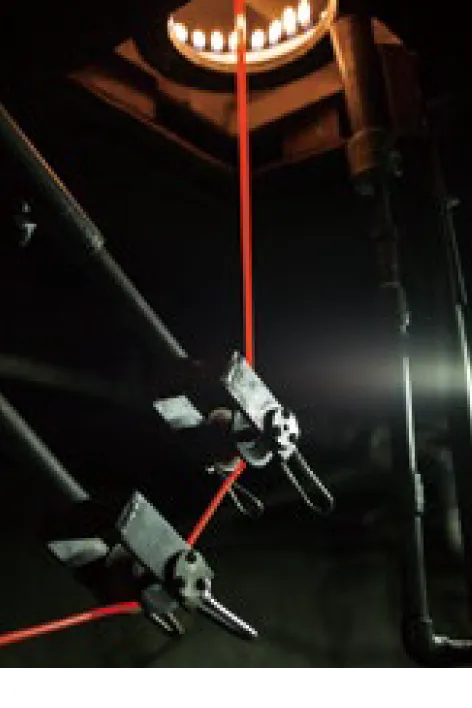

Filtering Canes

Raw canes are filtered by diameter by passing them through an inspection board with size-specific holes.

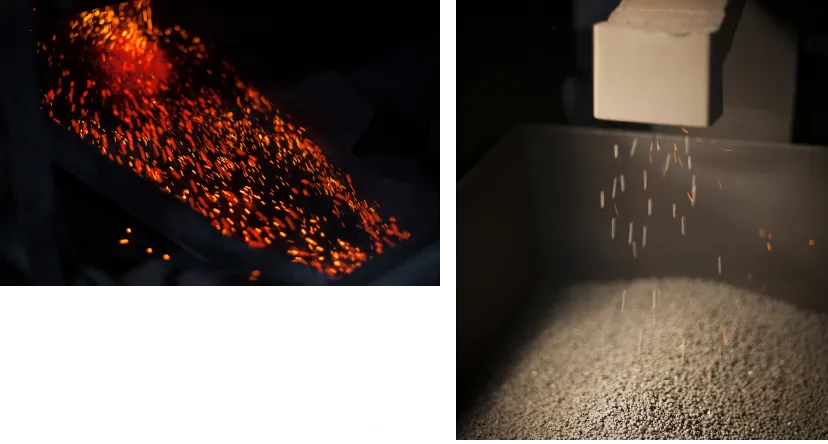

2. First Processing

Cutting

Canes are cut horizontally and at uniform lengths by a cutting machine.

Reheating

Heating the cut beads softens the edges, giving the beads a more rounded shape.

Rinsing

Beads are rinsed to remove any impurities from the surface.

Finishing

Since the surface of the rinsed beads are lightly frosted, they are heated again in order to melt just the surface and make them shiny and beautiful.

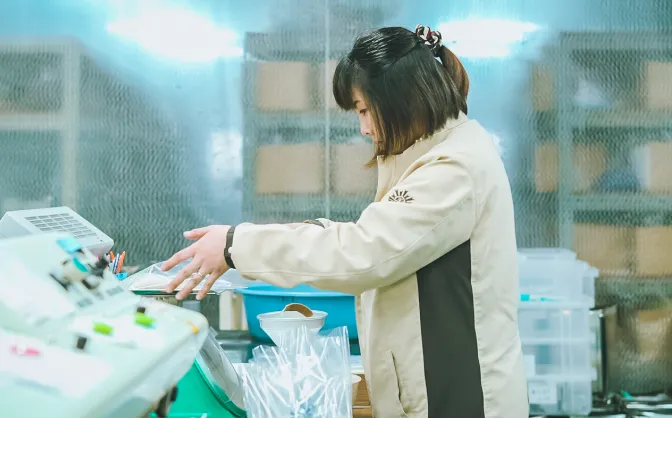

3. Bead’s Surface Treatment

Various secondary processes, such as plating, coloring, luster and rainbow coating are applied according to the desired color number.

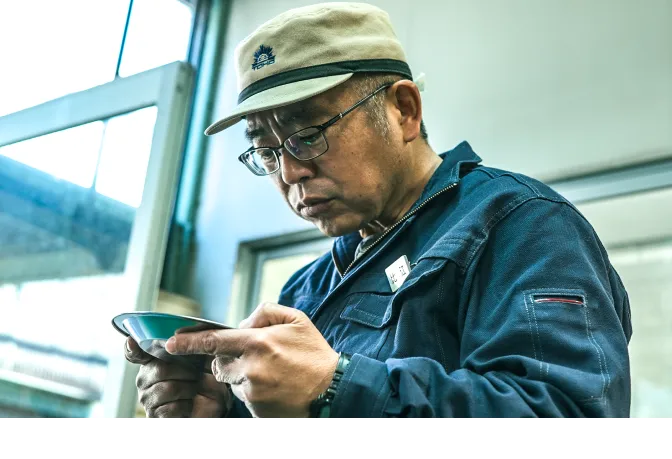

4. Quality Inspection and Packaging

Automated and manual detailed checks are done, after which the beads are carefully packed for shipment.